- Discover how we are helping Members reduce emissions: Explore the ProjectGHG hub now.

- Join the global DP Community at the IMCA DP Conference in Amsterdam. 21 and 22 May. Book now

- Register your interest for the IMCA Global Summit 2024. 3-4 December, Utrecht, Netherlands.

- Now booking. Underwater Ship Husbandry Seminar. 10 October 2024, Singapore.

Mooring near miss: Guide roller pin suffered material failure

What happened?

A deck stand guide roller pin suffered material failure at its foundation whilst a vessel was mooring. Weather, wind and tide conditions were gentle at the time of the incident and the vessel was being held in position using thrusters with no appreciable movement or excessive loads which could have contributed to this incident.

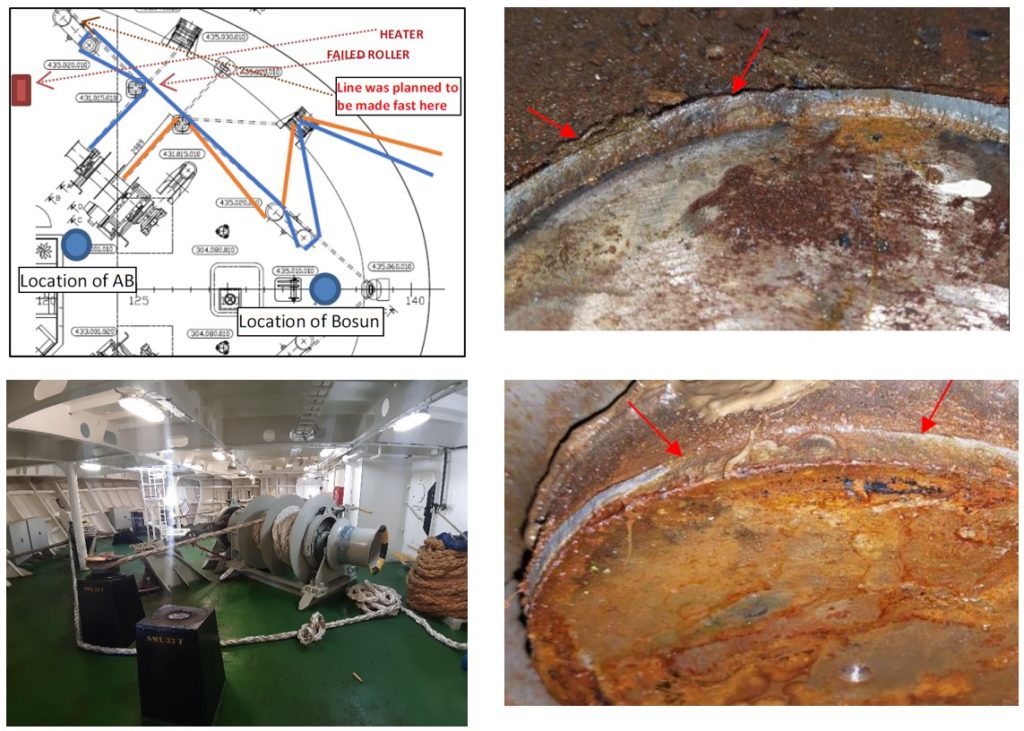

During mooring operations at the forward station when the 3rd head line (blue line in diagram below) was being heaved up using the warping head (the plan was to make it fast on a bollard to the aft of the failed roller) the deck stand roller pin parted from it’s base and hit a heater located just aft of this position.

There were no injuries. However, it is evident that any crew member standing in the line of fire of the damaged roller would have been seriously injured. The winch pulling force was 12 tonnes, the roller stand SWL was 33 tonnes.

What were the causes?

- The mooring layout on this vessel was complicated and also did not follow accepted and recommended practice, which caused overloading of structures;

- The routing of the mooring line caused an increase of axial forces on the roller;

- On further investigation it was noticed that roller pin was already in the process of degradation and at least some part of the welded structure had already disengaged from the base. The roller had not been inspected thoroughly;

- Multiple turns over various fittings increase the complexity of the mooring systems and introduce additional hazards such as complex snap back zones and overloading of structures.

Lessons learned

- Our member arranged to add to their Planned Maintenance System, dismantling and overhauling of deck stand guide rollers every third year;

- Ensure mooring plans use the most suitable and appropriate mooring arrangements;

- Avoid multiple turns which introduce complex snap back zones and additional hazards. Always discuss such risks as part of the daily planning and toolbox meeting;

- Be aware of your surroundings and of the line of fire.

Members may wish to refer to:

The following IMCA Safety promotional material and safety guidance is available to members:

Safety Event

Published: 1 April 2022

Download: IMCA SF 08/22

IMCA Safety Flashes

Submit a Report

IMCA Safety Flashes summarise key safety matters and incidents, allowing lessons to be more easily learnt for the benefit of all. The effectiveness of the IMCA Safety Flash system depends on Members sharing information and so avoiding repeat incidents. Please consider adding [email protected] to your internal distribution list for safety alerts or manually submitting information on incidents you consider may be relevant. All information is anonymised or sanitised, as appropriate.

IMCA’s store terms and conditions (https://www.imca-int.com/legal-notices/terms/) apply to all downloads from IMCA’s website, including this document.

IMCA makes every effort to ensure the accuracy and reliability of the data contained in the documents it publishes, but IMCA shall not be liable for any guidance and/or recommendation and/or statement herein contained. The information contained in this document does not fulfil or replace any individual’s or Member's legal, regulatory or other duties or obligations in respect of their operations. Individuals and Members remain solely responsible for the safe, lawful and proper conduct of their operations.